EXPLORE THE BENEFITS

WHY ESTERTEC?

EXPLORE THE BENEFITS

Enhanced Performance, Reliability, and Value - All in One Synthetic Ester Technology

In an evolving industry, synthetic lubricant components are becoming increasingly favored due to their superior performance, longevity, and environmental benefits. As market demands shift toward more-efficient and sustainable solutions, these components offer significant advantages, including enhanced oxidation stability, reduced friction and wear, and lower environmental impact. This trend not only supports longer equipment life and reduced maintenance costs but also aligns with global sustainability goals, making it an attractive choice for industrial and automotive applications.

At Zschimmer & Schwarz, we’re pleased to introduce EsterTec VSP technology, designed to meet evolving market demands for efficiency and sustainability. This innovative solution aligns with global environmental goals while delivering exceptional performance.

Boost Performance, Extend Life, Cut Costs - 5% (Average) Lower Density Delivers Value

- Improved cost performance economics

- Lower cost-per-unit volume due to lower density

- Wide temperature range performance (-60°C to 240°C)

- Improved control of friction and wear

- Energy-efficiency advantages

- Environmentally friendly, with ESG advantages

- High stability, long life, and low volatility

- Superior reduction of friction and wear

- Excellent heat transfer

- Good dielectric insulating properties

- Environmentally friendly, with high biogenic content

- High flash and fire points

- Compatible with PAO and petroleum-based stocks

- Suitable for use with standard elastomers

- Low density and high VI boost energy efficiency

All the Performance Advantages Expected from a Standard Diester or Polyol Ester, Plus ...

Equal or Better Performance Features:

- Pour Point

- Flash Point

- Foam Tendency

- Demulsibility

- Copper Corrosion

- Oxidative Stability

- Thermal Stability

- Specific Heat

- Thermal Conductivity

- Odor

- Color

- Clarity

- Miscibility with PAO

- Compatibility with Elastomers

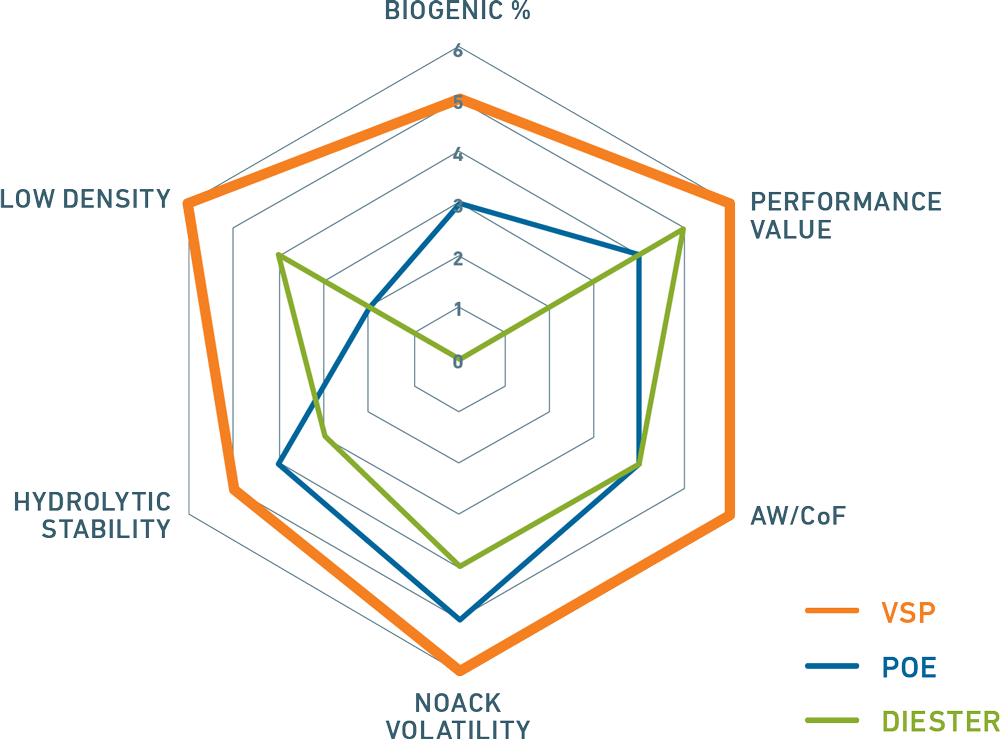

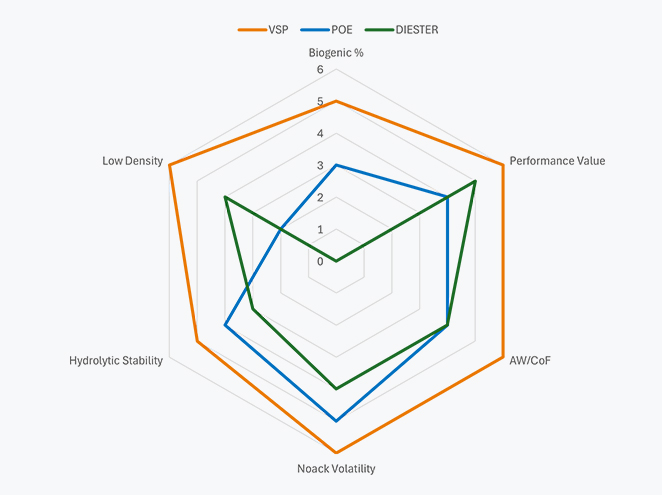

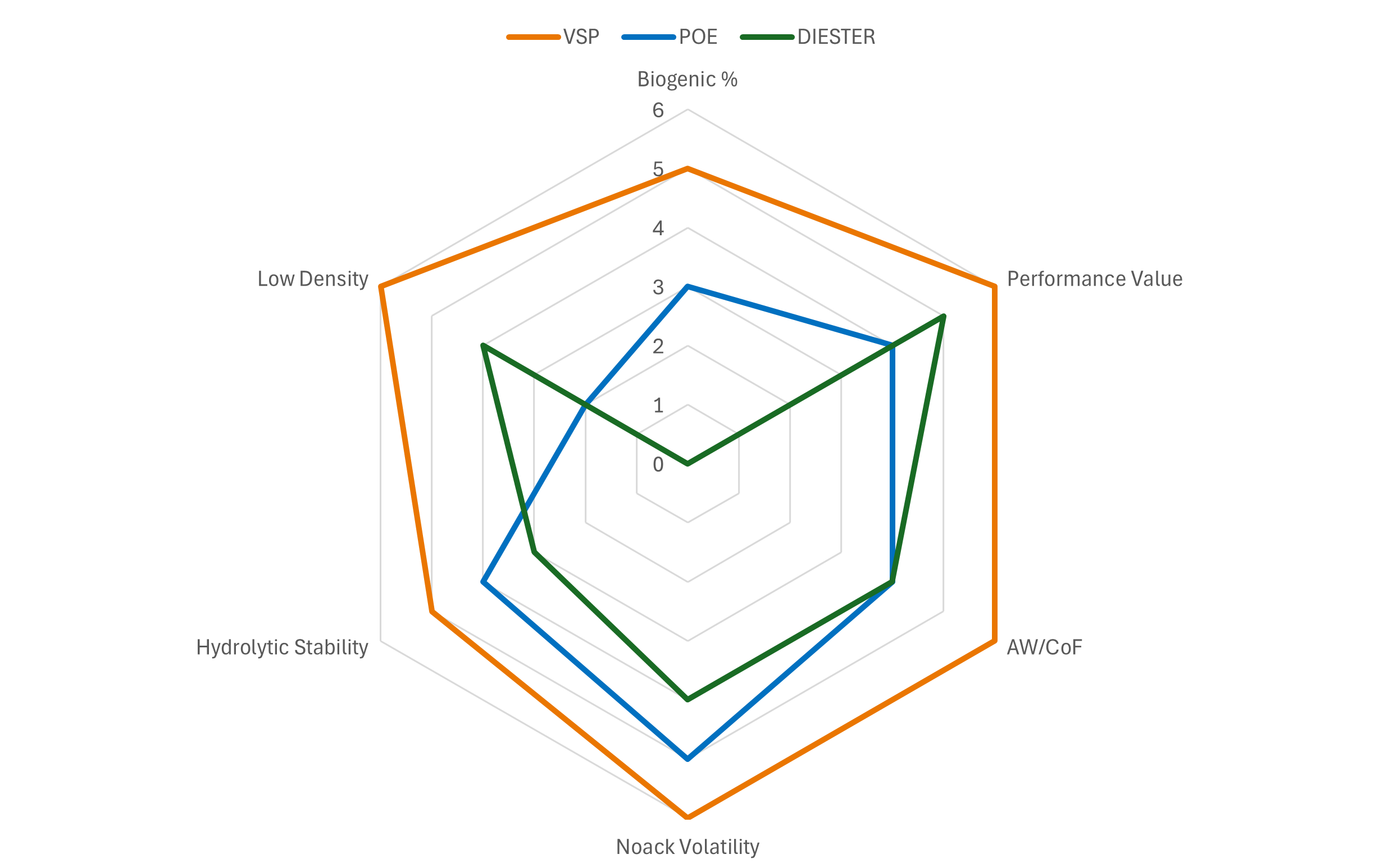

Estertec comparison radar chart

IMPROVED PERFORMANCE: ESTERTEC “VSP” ESTERS

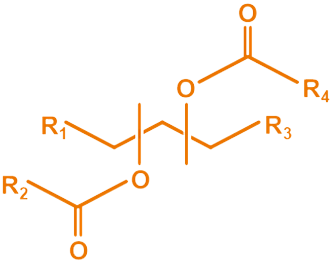

- Novel structure, due to a unique production process

- Standard raw materials that are globally and readily available commodities

- High stability vicinal ester molecular positioning

- Steric hindrance improves oxidative stability

- Secondary alcohols on adjacent carbons improve hydrolytic stability

ESTERTEC “VSP” Esters with Improved Performance

ESTERTEC VSP esters set a new standard for versatility and performance, making them the superior choice for a wide array of applications. Whether you’re formulating for today or planning for the future, EsterTec VSP esters deliver exceptional performance, reliability, and value.

Boost Performance, Extend Life, Cut Costs - 5% (Average) Lower Density Delivers Value

- Improved cost performance economics

- Lower cost-per-unit volume due to lower density

- Wide temperature range performance (-60°C to 240°C)

- Improved control of friction and wear

- Energy-efficiency advantages

- Environmentally friendly, with ESG advantages

- High stability, long life, and low volatility

- Superior reduction of friction and wear

- Excellent heat transfer

- Good dielectric insulating properties

- Environmentally friendly, with high biogenic content

- High flash and fire points

- Compatible with PAO and petroleum-based stocks

- Suitable for use with standard elastomers

- Low density and high VI boost energy efficiency

All the Performance Advantages Expected from a Standard Diester or Polyol Ester, Plus ...

Equal or Better Performance Features:

- Pour Point

- Flash Point

- Foam Tendency

- Demulsibility

- Copper Corrosion

- Oxidative Stability

- Thermal Stability

- Specific Heat

- Thermal Conductivity

- Odor

- Color

- Clarity

- Miscibility with PAO

- Compatibility with Elastomers

IMPROVED PERFORMANCE: ESTERTEC “VSP” ESTERS

- Novel structure, due to a unique production process

- Standard raw materials that are globally and readily available commodities

- High stability vicinal ester molecular positioning

- Steric hindrance improves oxidative stability

- Secondary alcohols on adjacent carbons improve hydrolytic stability

All the Performance Advantages Expected from a Polyol Ester, Plus …

- Natural energy-efficiency advantages from low density, high VI, and superior lubricity

- Best-in-class hydrolytic stability

- Excellent heat transfer and dielectric fluid properties

- High biogenic content compared to many synthetic polyol esters

Enhanced Performance, Reliability, and Value—All in One Synthetic Ester Technology

In an evolving industry, synthetic lubricant components are becoming increasingly favored due to their superior performance, longevity, and environmental benefits. As market demands shift toward more-efficient and sustainable solutions, these components offer significant advantages, including enhanced oxidation stability, reduced friction and wear, and lower environmental impact. This trend not only supports longer equipment life and reduced maintenance costs but also aligns with global sustainability goals, making it an attractive choice for industrial and automotive applications.

At Zschimmer & Schwarz, we’re pleased to introduce EsterTec VSP technology, designed to meet evolving market demands for efficiency and sustainability. This innovative solution aligns with global environmental goals while delivering exceptional performance.

Boost Performance, Extend Life, Cut Costs— 5% (Average) Lower Density Delivers Value

- Improved cost performance economics

- Lower cost-per-unit volume due to lower density

- Wide temperature range performance (-40°C to 200°C)

- Improved control of friction and wear

- Energy-efficiency advantages

- Environmentally friendly, with ESG advantages

- High stability, long life, and low volatility

- Superior reduction of friction and wear

- Excellent heat transfer

- Good dielectric insulating properties

- Environmentally friendly, with high biogenic content

- High flash and fire points

- Compatible with PAO/petroleum-base stocks, as well as standard elastomers

- Low density and high VI boost energy efficiency

All the Performance Advantages Expected from a Standard Diester or Polyol Ester, Plus ...

Equal or Better Performance Features:

- Pour Point

- Flash Point

- Foam Tendency

- Demulsibility

- Copper Corrosion

- Oxidative Stability

- Thermal Stability

- Specific Heat

- Thermal Conductivity

- Odor

- Color

- Clarity

- Miscibility with PAO

- Compatibility with Elastomers

EsterTec “VSP” Esters with Improved Performance

- Novel structure, due to a unique production process

- Standard raw materials that are globally and readily available commodities

- High stability vicinal ester molecular positioning

- Steric hindrance improves oxidative stability

- Secondary alcohols on adjacent carbons improve hydrolytic stability

All the Performance Advantages Expected from a Polyol Ester, Plus …

- Natural energy-efficiency advantages from low density, high VI, and superior lubricity

- Best-in-class hydrolytic stability

- Excellent heat transfer and dielectric fluid properties

- High biogenic content compared to many synthetic polyol esters