FREQUENTLY ASKED QUESTIONS

FREQUENTLY ASKED QUESTIONS

WARRANTY

The Penrod Company warrants its products against manufacturing defects under normal use for a period of one year after delivery. This warranty does not cover defects or damage due to improper use or handling of material, ordinary wear and tear, or any misuse. The liability shall be limited to replacement or repair of any product supplied by Penrod. Penrod will accept no claims unless given proper notice and an opportunity to examine the claimed material and installation. Warranty will automatically be considered void for hinges and hardware subjected to any foreign substances or cleaning agents other than a mild warm water and soap solution. This solution must be wiped off the hinge with a dry, clean rag immediately following use.

REPLACEMENT AND REPLACEMENT IDENTIFICATION

We do not currently sell to the public or have the capability to distribute directly on a retail level. If you are looking for new or replacement products, we recommend that you search for a local door supply manufacturer or door hardware retailer.

Door hinges are a component of a door that can be manufactured locally, regionally, nationally, or even internationally. Most doors have hinges produced to meet the specifications of an individual door manufacturer. Combine that with the many times those specifications may have changed over the years and the result is, there’s a tremendous variety of hinges on doors still hanging today.

Since it is difficult to determine what hinge you may have, it’s best to look for a manufacturer’s label on the door to identify who made it, where it may have been purchased, and how long ago it was purchased, before contacting a manufacturer or door hardware retailer.

In many cases, commonly found hinges can be retrofitted on an existing door, but may require drilling or tapping of new holes. Drilling new holes in a wood, fiberglass, or engineered material such as MDF door is typically the easiest, with steel doors and frames being the most difficult since this generally requires a tap and die.

We recommend that you contact a professional for any door re-work as this can alter the doors functionality and can negate any testing certificates or code compliance.

GENERAL

A door may squeak over time for a variety of reasons. Door weight, balance of frame at installation, and even home settling can all be factors. Oiling and greasing is recommended. A low-viscous option such as WD-40 is a short-term solution. A heavier lubricant such as white lithium, one that’s lanolin-based, silicone or other synthetic greases are most recommended for duration.

We do not currently produce or offer to market any hinges with steeple or decorative tips.

You can remove a hinge pin on a hinge without a non-removable pin (NRP) feature by taking a pick and hammer and tapping the bottom of the hinge. *It is not recommended to remove pins on ball bearing hinges. These contain casings with small bearings inside and removing pins can result in damage from the loss of micro bearings.

Some door hinges can be painted, though it’s not recommended. Why? Hinges are moving parts and paint will not adhere to these areas, so their appearance over time will likely not be very attractive. Painting can also change the functionality of a hinge, which can lead to improper opening and closing of the door.

In cases where painting is still desired, take note that US2D Zinc Dichromate and LUS15 Dull Nickel are the two finishes recommended for the best paint adhesion. Also, a high-quality latex paint such as Sherwin Williams Pro Max 200 or higher is recommended. Next, these are the steps we recommend:

- Wipe the surface using only water or a mild soap solution and dry immediately.

- Do not scuff, sand or prep the surface with any agents such as thinner, lacquer remover, or alcohol.

- Use paint at 100% strength; do not thin it.

- Two coats are recommended, allowing two hours between coats.

- Allow the paint to cure for twenty-four hours before hanging or operating the hinge.

Black dust is caused by metal riding on metal. There is no way to prevent this from occurring entirely, but it is recommended to use a ball bearing hinge to prevent most dust, especially on heavier doors.

The difference between a plain bearing hinge and a ball bearing hinge is that a plain bearing hinge does not have a buffer between the connecting knuckle leaves when the hinge pin is inserted. A ball bearing hinge has a ring casing between these two points of contact with ball bearings inside, which in turn causes less friction when the hinge is opened and closed.

The result is a more fluid and quiet motion when opening and closing the door, with far less hinge dust over time that often develops on regular hinges when the steel knuckles ride against each other.

Security hinge features vary. The purpose is to prevent being able to easily remove a hinge pin on a door that swings out from the outside. We offer three main types:

Riveted Outswing Feature – This is a hinge that has a rivet placed at the bottom of the barrel. Tested to not come loose with prying; to remove, drilling is required. This is the most common choice as it is effective for security and is attractive on a door at any position.

Non-Removable Pin (NRP) Feature – This is a hinge that has a hole bored through the barrel with a set pin placed connecting the hinge barrel and hinge pin, which prevents the pin from being easily removed. This feature is visible on a closed and opened door unit.

Security Stud Feature – A security stud is a feature in a hinge that has a hole in one leaf and an offset in the other leaf; these interlock when the door is closed, preventing the removal of a hinge if the pin is removed. This feature is visible on an opened door unit, but not seen when a door is closed.

A hinge swage is the offset bend of a hinge that makes it parallel upon closing. There are many different varieties of swaging sizes. The most common residential swages are:

- #1 Swage is a standard spec. The gap to parallel is 1/16”

- #2 Swage is a custom callout specification. The gap to parallel is 1/8”

All spring hinges we manufacture are grade 1 and are UL-listed stamped on the hinge.

PROPER HANDLING AND CARE

The majority of hinges and hardware items found on pre-assembled doors or home packages are electroplated finishes, which can react with and immediately be damaged by most cleaners. It is not recommended to use any cleaner or substance other than a mild soap-and-water solution to wipe clean. It is important to immediately dry all surface areas once they are cleaned to prevent a reaction or damage to the finished surface.

It is also recommended to remove or cover all door hardware, including door hinges, if cleaners are used on a dwelling’s exterior. Many of the common whole-house cleaners that attach to a hose or are sprayed with power washers are likely to damage and/or promote oxidation or delamination of many finishes.

FOR INSTALLATION:

FOR INSTALLATION:

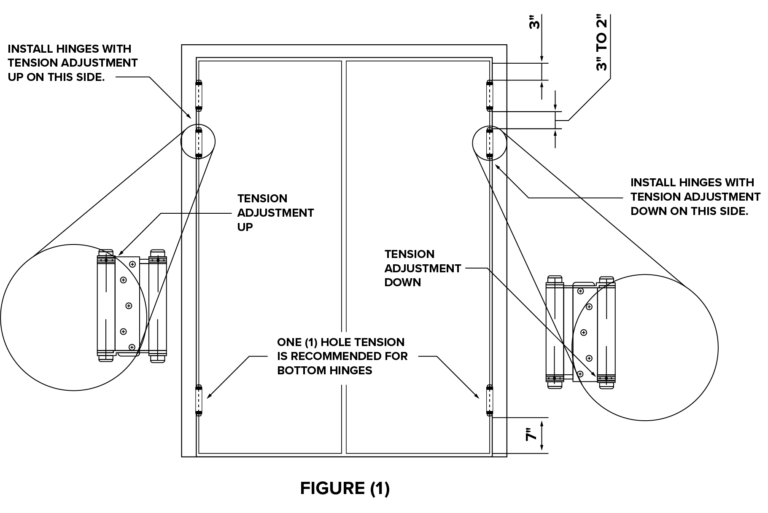

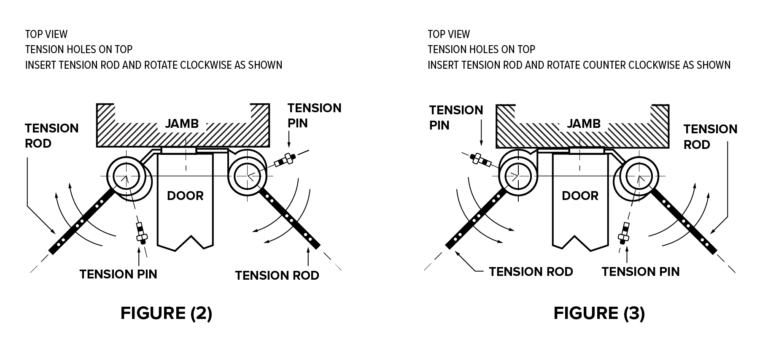

Remove the spring tension from each barrel on the hinge by inserting a tension rod into the tension adjustment hole, and then rotating it in the direction of the arrow, as shown in Figure 2 or Figure 3. Remove the tension pin.

Align the centerline of the door with the centerline of the frame and secure the frame leaf.

For best alignment of self-closing double doors, mount your hinges on one door with the tension adjustment up, and then adjust the tension down on the opposite door as shown in Figure 1. Shims may be necessary under the edges of the frame flanges for door alignment.

FOR SPRING TENSION ADJUSTMENT:

FOR SPRING TENSION ADJUSTMENT:

-

- Place the door in a closed position, then wedge the door up from the floor until it is plumb.

- Insert a tension rod into the tension adjustment hole, rotate the rod in the direction of the arrow, as shown in Figure 2 or Figure 3. (Only one hole of tension is recommended for bottom hinges.)

- Insert a tension pin, and remove the tension rod.

- Increase tension on the top hinges if the door sags or the return action is too slow.

CAUTION:

Do not exceed five (5) holes of tension.

FOR INSTALLATION & ADJUSTMENT:

FOR INSTALLATION & ADJUSTMENT:

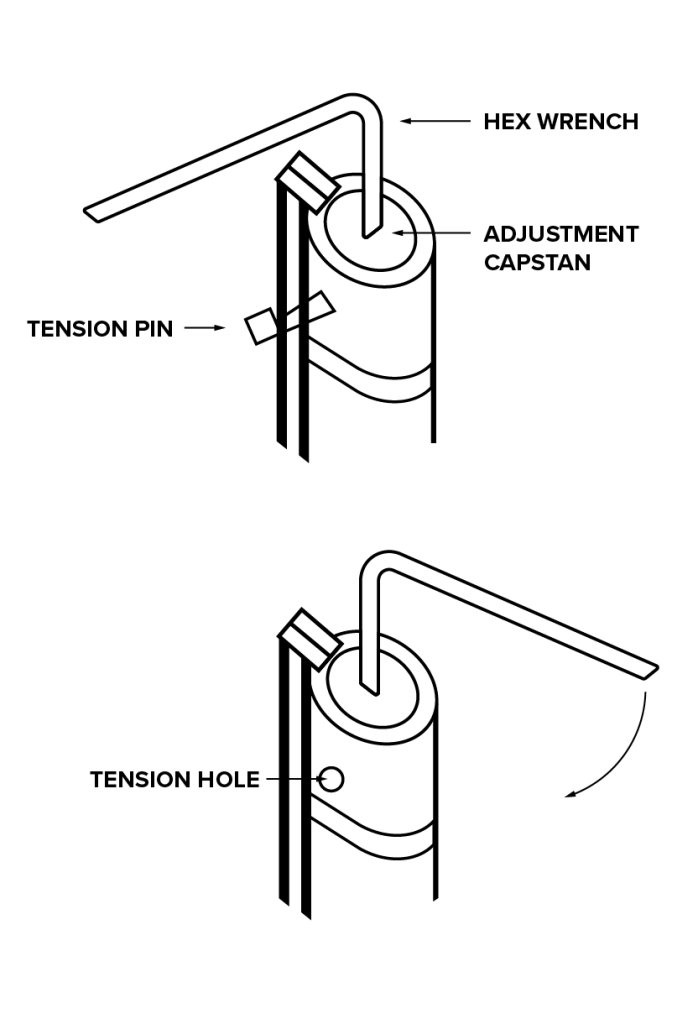

- Attach the spring hinge to both doors and jambs so the hinge leaf with the UL logo is attached to the jamb. (The hex adjustment may have to face down.)

- Place the door in a closed position.

- If the hex adjustment cylinder is facing up, turn the hex wrench clockwise to the desired tension. If the hex adjustment cylinder is facing down, turn the hex wrench counterclockwise to the desired tension.

- Insert the tension pin into the tension hole when the holes in the center stud and the hinge knuckle line up. Slowly release the tension on the hex wrench.

- Remove the hex wrench and test the closing action of the door.

- Repeat Steps 1 through 5, if necessary, to increase or decrease the tension of the spring hinge.

CAUTION:

- Do not exceed three (3) holes of tension for doors opening 180 degrees, and do not exceed four (4) holes of tension for doors opening 90 degrees.

- Adjust the spring hinge to the minimum tension required to close the door. Over-tensioning will reduce the spring life.

PROPER HANDLING AND CARE

Proper handling of higher-end hinges and hardware products—such as ball bearing, stainless steel-based hinges—for small residential projects, is vastly different than commodity units with common, electroplated, steel-based hinges delivered in high quantities for large construction projects. It’s important for door hangers and suppliers to consider all aspects of building construction and communicate to project managers, foremen and other supervisors the proper handling and care of hinges and hardware products.

Cull or throwaway hinges are recommended for use on an unfinished door or door unit that will be finished at a later date. This is because installation, taping and painting, as well as general construction, clean up and other activities can lead to damage. For more information if cull or throwaway hinges are not used, go to our Oxidization (Rust) and Finishing answer for important information.

It is not recommended to remove hinge pins on ball bearing hinges. These contain casings with small bearings inside and if hinge pins are removed, the hinges can be damaged by the loss of micro bearings.

If painting will be done after a unit is installed, removing all door hardware is recommended. Any hardware not removed should be well covered and/or taped using a recommended low-adherence painter’s tape such as Scotch™ Blue or a lighter grade tape.

It is important to keep paint from getting on your hinges as many chemicals in paint itself can damage the finishes on your hinges. This is also true for cleaners that contain chemicals.

In cases where painting is still desired, take note that US2D Zinc Dichromate and LUS15 Dull Nickel are the two finishes recommended for the best paint adhesion. Also, a high-quality latex paint such as Sherwin Williams Pro Max 200 or higher is recommended. Next, these are the steps we recommend:

- Wipe the surface using only water or a mild soap solution and dry immediately.

- Do not scuff, sand or prep the surface with any agents such as thinner, lacquer remover, or alcohol.

- Use paint at 100% strength; do not thin it.

- Two coats are recommended, allowing two hours between coats.

- Allow the paint to cure for twenty-four hours before hanging or operating the hinge.

If taping a hinge, it is important to follow these steps to prevent damage and ensure longevity:

- Select a low-adhering tape such as Scotch™ Blue or a lighter-grade tape. Heavier graded tapes (such as general masking tape) is not recommended and will damage most common finish plating.

- Tape thoroughly, covering all areas. Paint ingredients will cause damage when wiped or over sprayed on the surface.

- Remove tape immediately after painting.

- Do not clean with solvents or foreign substances including, but not limited to, thinner, lacquer remover or alcohol.

- General hinge and hardware cleaning instructions are to use a mild warm soap and water solution, then immediately drying with a clean rag.

Some door hinges can be painted, though it’s not recommended. Why? Hinges are moving parts and paint will not adhere to these areas, so their appearance over time will likely not be very attractive. Painting can also change the functionality of a hinge, which can lead to improper opening and closing of the door.

In cases where painting is still desired, take note that US2D Zinc Dichromate and LUS15 Dull Nickel are the two finishes recommended for the best paint adhesion. Also, a high-quality latex paint such as Sherwin Williams Pro Max 200 or higher is recommended. Next, these are the steps we recommend:

- Wipe the surface using only water or a mild soap solution and dry immediately.

- Do not scuff, sand or prep the surface with any agents such as thinner, lacquer remover, or alcohol.

- Use paint at 100% strength; do not thin it.

- Two coats are recommended, allowing two hours between coats.

- Allow the paint to cure for twenty-four hours before hanging or operating the hinge.

The result is a more fluid and quiet motion when opening and closing the door, with far less hinge dust over time that often develops on regular hinges when the steel knuckles ride against each other.

OXIDIZATION (RUST) AND FINISHING

Standard steel-based finished, plated hinges and hardware products meet or exceed the industry minimum standard; Penrod produces to a much higher-than-minimum standard to provide the highest quality finished product.

Oxidization (rust) is eventually going to occur over time on all steel-based plated products. This process will be accelerated, if not begin to immediately occur, from

- Excessively humid or wet environments

- Building designs that do not wick and/or capture moisture

- Foreign cleaning agents applied directly to, wiped on, or sprayed on that delaminate the finish

- Paint drippings, splatter, or overspray

- General misuse

We recommend using a stainless steel or stainless steel-based product if you will be in excessively wet or humid environments, or if the design or building application limits drying out from weathering. It is important to keep foreign agents away from these products, and if cleaning them, to do so only using a warm-water and mild-soap solution. Please refer to our limited warranty for more details.

All our stainless steel products are a 304 grade. This is to provide the highest quality and most resistance to oxidization (rust). 304 grade hinges are not recommended in marine environments, which is direct physical contact with salt water. We recommend a 316 grade hinge, which can be reviewed for special lead time production.

Since it is difficult to determine what hinge you may have, it’s best to look for a manufacturer’s label on the door to identify who made it, where it may have been purchased, and how long ago it was purchased, before contacting a manufacturer or door hardware retailer.

In many cases, commonly found hinges can be retrofitted on an existing door, but may require drilling or tapping of new holes. Drilling new holes in a wood, fiberglass, or engineered material such as MDF door is typically the easiest, with steel doors and frames being the most difficult since this generally requires a tap and die.

We recommend that you contact a professional for any door re-work as this can alter the doors functionality and can negate any testing certificates or code compliance.

ANSI/BHMA/NFPA 80/FIRE RATING/SPRING GRADING

Each of our residential and standard grade 1 commercial spring hinges are certified and stamped on the hinge with the grade rating and UL registration number.